Leaky Showers made by Tilers

Most tile showers constructed on-site by tilers are waterproofed with either painted-on acrylic or polyurethane membranes / coatings. These coatings are only about 1mm thick, and are prone to deterioration due to numerous factors, many of which are beyond the control of the waterproofer / tiler. Most leaky showers take years for the catastrophic, expensive damage of rotting of flooring and framing to show.

Some of the reasons for membrane failures are the following:

- Unseen pin-holes, insufficient thickness and coverage of the paint coating – all due to poor workmanship

- Membranes become less flexible over time and may crack on both timber and concrete floors due to building movement and expansion/ contraction from humidity and temperature changes.

- Chemical break-down and physical changes of membranes can occur over time due to constant contact with water under the tray tile.

The slow, undetectable damage caused by leaky showers can cost thousands of dollars to repair and is most-often not covered by insurance companies.

Even proficient, experienced waterproofing applicators have had multiple leaky showers.

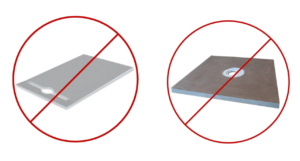

Avoid waterproofing failure commonly seen with low-cost foam bases, and cement-plaster screeded shower floors.

Only a true one-piece shower base / tray with actual sides, can reliably contain water – Impresa guarantees leak-free showers for 25 years.

Waterproofing Compliance

To comply with the NZ Building Code, a waterproof membrane must be applied to permeable shower wall linings (typically plasterboard, fibre- cement board) to prevent moisture penetration. The applicator is to have been trained and licenced by the membrane manufacturer or it’s representative, hold a current licence, and be registered with the local council.

Building Consent / Producer Statement (PS3)

Shower Wall Waterproofing

Where a shower is being installed and is subject to a building consent, and before a Code of Compliance Certificate can be issued by the local building authority / council, a licenced waterproofing applicator must provide a Producer Statement (PS3) stating the practitioner’s current licence number for the workmanship, the waterproofing membrane brand name, and the manufacturer’s warranty statement.

Impresa Shower Trays

Impresa shower trays are inherently watertight and waterproof, therefore a PS3 is not required by the local building authority / council. However, they may request a warranty statement – see the warranty statement supplied with the shower or download and print the PDF herein the website.

Frequently Asked Questions

Why do most tile showers leak?

Most tile showers are waterproofed with acrylic-based paint-on membranes which are often too thin, become brittle over time, and split as they cannot cope with building movement. However leaking can occur for many reasons – detrimental ambient conditions/poor drying between coats; insufficient coating coverage; over-use of glass fibre reinforcement/ insufficient coverage thereof; structural movement between the shower base and walls causing cracks in the membrane; cracks in concrete-plaster bases and joins of foam bases causing acrylic paint-on and polyester resin coatings to split. In some instances the membrane resins are prone to breaking-down. Many showers are constructed using the wrong type of drain/ wastes, some of which have been designed for use with plastic shower trays. Membranes such as polyester/ fibre glass resin do not even adhere to the most commonly used drain-flange meaning water can seep under the waterproofing from day one!

Why are my shower floor tiles cracked?

A foam base may have been installed under the tiles and not glued down adequately. Insufficient adhesive/poor adhesion of the foam allows the foam to flex when the shower is in use. The flexural movement may result in the cracking of the waterproofing and a leak will occur. Also, cement screeds can crack destroying the waterproofing membrane. The result of a leaky shower is swelling and rotting flooring, and timber framing and joists.

Do I need a shower tray when I have a concrete-floor?

Whilst some tilers are conscientious, others do not take waterproofing seriously enough. They simply apply a paint-on membrane without a full appreciation of the high risk of membrane failure. Over time, concrete floors can crack causing the membrane to fail and a devastating leak to occur. Showers on concrete floors should have a shower tray to prevent water seeping into the concrete and eventually into the surrounding timber framing.

My builder and tiler both say they have never had a shower leak – why do I need an Impresa Stile or metro shower system?

Chances are they have built a shower that has subsequently failed, but they are just not aware of it. A high percentage of tile showers will eventually leak. Most times a leaky shower cannot be repaired, but will need to be ripped-out and re-constructed, costing thousands of dollars.

What is a tile shower system?

A tile shower system is centred around a pre-formed tray and integrated frameless glass enclosure. The Stile and Metro shower systems incorporate a durable, one-piece aluminium shower tray (guaranteed 25 years), wall waterproofing membrane, and a 10mm frameless-glass enclosure. As compared to traditionally-made tiled showers, our tile shower systems are quicker, more cost-effective, and are guaranteed not to leak.

What sizes and shapes are Stile and Metro showers supplied in?

Stile and Metro showers are available in over 30 standard shapes and sizes and also available in custom-size trays and glass screen enclosures. See the Price Guide or contact Impresa for pricing.

Does Impresa supply custom-made showers?

Impresa can manufacture virtually any custom size or shape shower tray and frameless screen enclosures. Refer to Custom Sizes for details.

What’s included in an Impresa tile shower system?

Both the Stile and the Metro tile shower systems provide a tile shower tray, frameless glass screen enclosure, easy-clean waste-trap and stainless-steel grate (Stile), drain-channel cover (Metro), tray to wall waterproofing connection tape. A full waterproofing kit for the shower walls is optional.

Can I install an Impresa shower myself and retain the warranty?

Yes. Anyone can install the tray and retain the Impresa Platinum 25 Year Leakproof Guarantee (subject to the approved method of installation). The Impresa shower tray warranty applies to the manufacturing quality and performance of the shower tray only. Whilst the method of installation of the tray is simple, no warranty for the installation outcome is implied nor expressed. If you intend to utilise a paint-on waterproofing membrane on the shower walls ensure a registered applicator is employed.

Impresa Wrap – if this membrane is supplied for application to the shower walls, and a building consent has been issued with a producer statement later required, it is necessary for the membrane to be applied by an approved licensed applicator. A 15-year warranty applies to applications where an approved installer is utilised.

Frameless glass – It is advisable to have a qualified frameless glass glazier install the glass enclosure to ensure the best watertight seal and provide a clean installation. The glass is warranted for 10 years and the hardware is warranted for 5 years.

How do Impresa tile shower systems compare with other showers?

Impresa has been manufacturing and distributing standard and custom-made integrated tile shower systems for over 10 years. The shower trays are manufactured from a heavy-duty, epoxy-coated, marine-grade aluminium making them the strongest and most durable tray world-wide. Specialising in tile shower systems, Impresa has only one focus – providing the very best shower design combined with durability and functionality. For many of New Zealand’s specifiers we are the recognised leader in custom-designed tile shower systems.